3000W Laser Cutting Machine

In the case of the same thickness and the same material, the cutting speed of the metal laser cutting machine has a certain connection with the power of the laser cutting machine, so everyone must not ignore it when choosing a laser cutting machine . The material of the workpiece to be cut is different, and the cutting speed is also different. Common cutting materials: carbon steel, stainless steel, the cutting speed is faster, cast iron is slightly slower, followed by aluminum, and copper is particularly slow. Because copper and aluminum are more difficult to cut, the cutting speed is higher.

The first two are much slower, and the cutting thickness is much smaller when plasma cutting copper and aluminum with the same power than stainless steel and carbon steel. Different powers and different gas speeds are different, take 1mm stainless steel as an example. Common laser powers on the market include 500W metal laser cutting machine, 700W metal laser cutting machine, 1000W metal laser cutting machine, 1500W metal laser cutting machine, 2000W metal laser cutting machine, 2400 metal laser cutting machine, 3000 metal laser cutting machine, etc.

The laser equipment is between 500W-3000W, which is a medium power laser equipment. Laser cutting machine is for reference only, the actual laser cutting speed is subject to the instructions of different models of laser cutting machines with different performance.

Igolden laser is a private technology enterprise integrating production, research and development, and sales. The company's main products: optical fiber marking machine, optical fiber cutting machine, laser cleaning machine, laser welding machine, vibration knife cutting machine, products are widely used in electronics, clothing, leather, handicrafts, sheet metal, packaging and printing, advertising, decorative home textiles, etc.

Multiple areas. The company has always been adhering to the corporate tenet of "impress customers with quality, convince customers with quality, return customers with quality, and retain customers with quality", and its technical strength, high-quality equipment quality and advanced service concepts have been recognized by customers. Igolden Laser will continue to provide users with high-quality, high-performance products and fast and complete services. Leaders and friends from all walks of life are welcome to visit and guide the work.

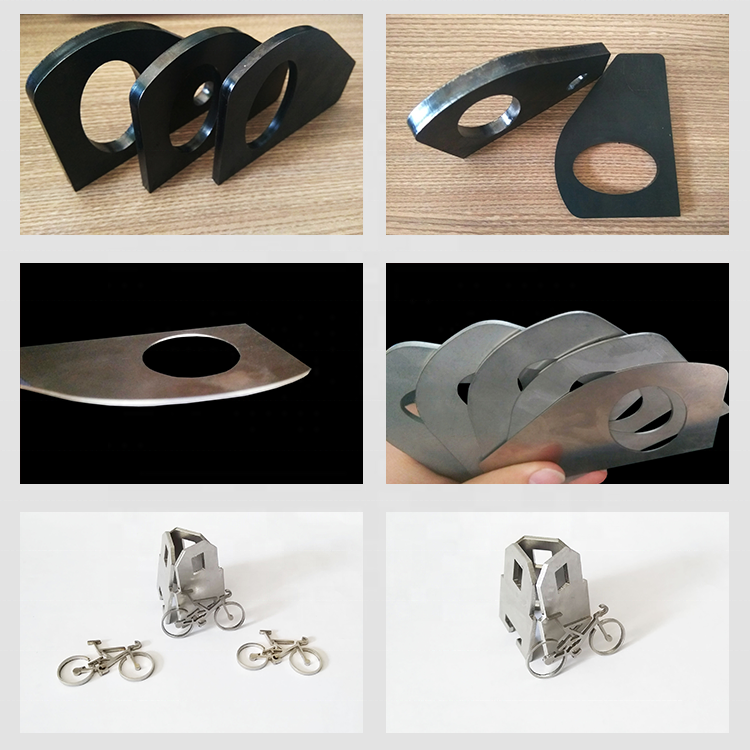

After purchasing the fiber metal sheet laser cutting machine, there is no need to debug the metal sheet fiber laser cutting machine to ensure normal operation. This is also an inspection location, depending on the cutting quality, which is a direct way to inspect the quality of the equipment. For new customers, when purchasing equipment, they will be asked to see DIY fiber laser cutting machine proofing. In addition to the cutting speed of the equipment, proofing also depends on the cutting quality of the sample. So how to look at cutting quality and pay attention to certain aspects. Let me introduce it in detail below.

1. Verticality When the thickness of the plate exceeds 10mm, the verticality of the blade is important. When away from the focal point, the laser beam will diverge, depending on the position of the focal point, the incision widens up or down. Well, the more vertical the edge, the higher the cutting quality.

2. Average The laser cut part will form a vertical line. The depth of the line determines the displacement of the cutting surface. The lighter the line, the smoother the cut. It hardly affects the appearance of the edges, but it also affects the friction characteristics. In most cases, the large value needs to be reduced, so that the lighter the texture, the better the cutting quality.

3. Texture As a result, curved lines are formed on the cutting edge, and these lines closely follow the moving laser beam. When cutting thick plates at high speed, the molten metal will not appear under the vertical laser beam, but will be ejected to the rear of the laser beam. In order to solve this problem, the feed speed at the end of the cutting process can greatly increase the formation of lines.

4. Cutting width the approximate width generally does not affect the cutting quality. Only when a special contour is formed inside the part does the cutting width have an important effect. This is because the cutting width determines the small internal warpage of the profile. When the thickness of the plate increases, the cutting width also increases arbitrarily. Therefore, if the same height is to be guaranteed, the metal processing area of the fiber laser cutting machine should be constant regardless of the length or width of the workpiece.

评论

发表评论