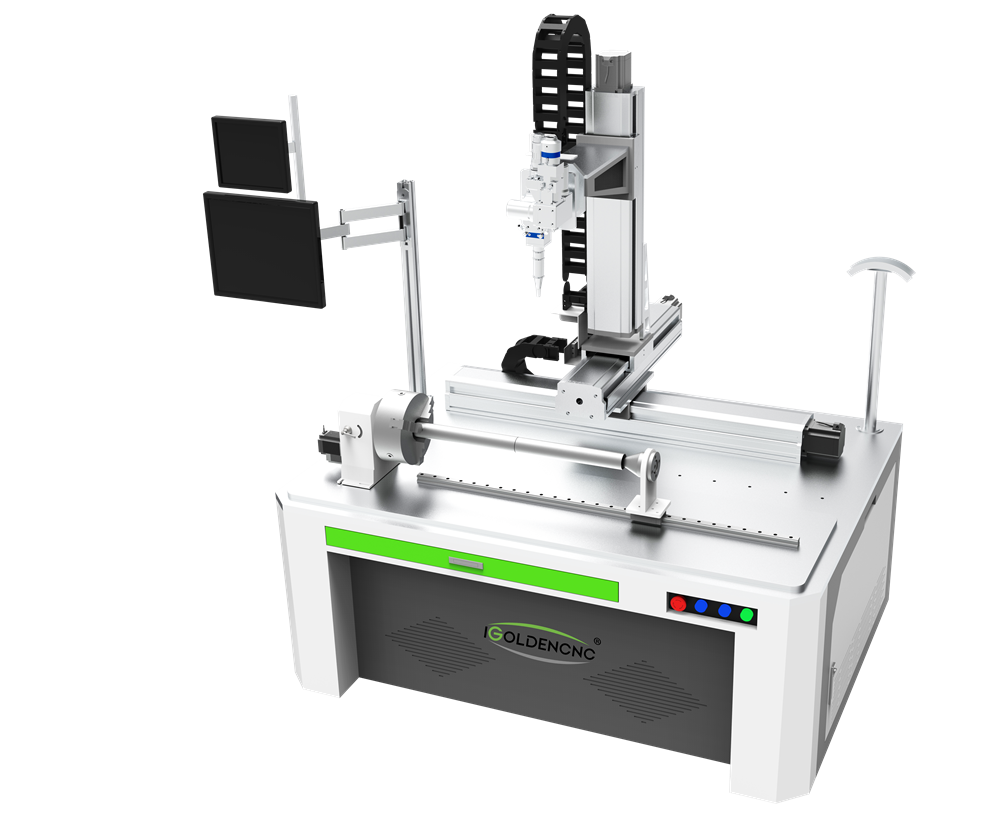

Automatic Laser Welding Machine Price

Igolden automatic laser welding machine can be used for all kinds of precision welding, industrial swing welding, computer scanning welding operation, it has low manual requirements, and the welding line is beautiful, and the welding seam is thinner. Product features of the automatic laser welding machine:

1. Dedicated fiber laser, water-cooled design, easy to operate.

2. The site requirements are low, and the workstation can be adjusted at any time, which is convenient and flexible.

3. Fast speed and high efficiency.

4. The operation is simple and easy to learn, and the operator's experience is low and the weld is beautiful.

5. The welding speed is fast, and the efficiency is more than 2 times that of YAG laser welding and 3-5 times that of argon arc welding.

Automatic laser welding machine application industries: mobile phone industry, medical equipment industry, clock and watch industry, electronics industry, precision machinery industry, communication industry, metal processing industry.

Applicable materials: stainless steel, carbon steel, gold, silver, aluminum, aluminum alloy, titanium alloy, etc., splicing of dissimilar materials.

When using a laser welding machine to weld processed materials, we must always pay attention to the changes in the processing parameters, and always pay attention to whether there is a deviation in the processing parameters, to prevent processing failures during the welding process of the laser welding machine. Let's talk about it below. What are the effects of the processing parameters of the laser welding machine on the processing process?

Impact 1. The power density of the laser welding machine will affect the welding effect

In the laser welding process, we must always pay attention to the changes of power density parameters. Under high power density conditions, the surface layer can be heated to boiling temperature in a very short time, resulting in significant vaporization. Therefore, under the condition of high-power density, the processing technology of a variety of materials can be improved. Under the condition of low power density, the surface layer needs a long time to reach the boiling temperature, so the bottom layer will begin to melt before the surface layer reaches the boiling point, thereby optimizing the welding effect. Therefore, pay attention to the laser welding machine in the processing process, the power density of the welding machine is best controlled at 104~106W/cm2.

2. The laser pulse waveform of the laser welding machine will affect the material loss of the workpiece

In the laser welding process, the pulse waveform of the laser is also a problem worth noting, especially when processing thin workpieces. In the laser welding process, most of the laser light will be lost due to the reflection of the metal surface, and this reflection will change with the temperature of the surface. During the laser welding process, the pulse waveform of the laser will constantly change.

3. The laser pulse width of the laser welding machine will affect the melting effect of the material

The pulse width of the laser is a key prerequisite for distinguishing between material removal and melting, and it is also an important parameter for determining the price and size of the equipment required in the welding process.

4.the defocusing amount of the laser welding machine will affect the welding quality

In the laser welding process, sometimes the focus of the laser may be too high to cause holes on the surface. Therefore, the defocus operation must be performed before laser welding. After the defocus operation, the laser will be scattered on each surface, and the laser power density will be evenly distributed at this time.

评论

发表评论