Cutting speed and effect of fiber laser cutting machine

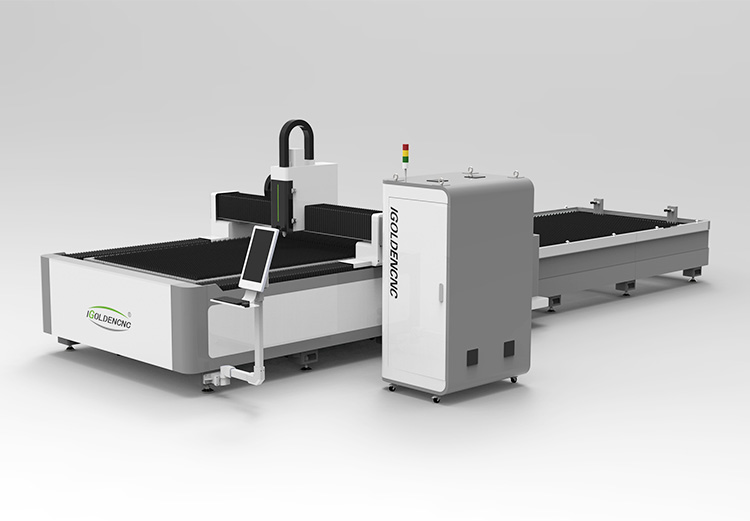

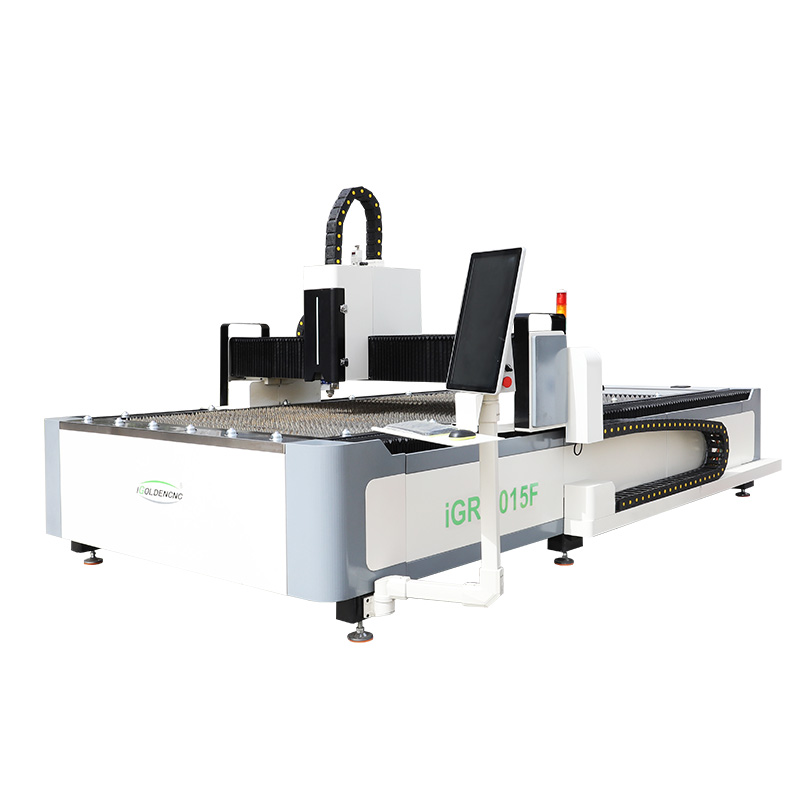

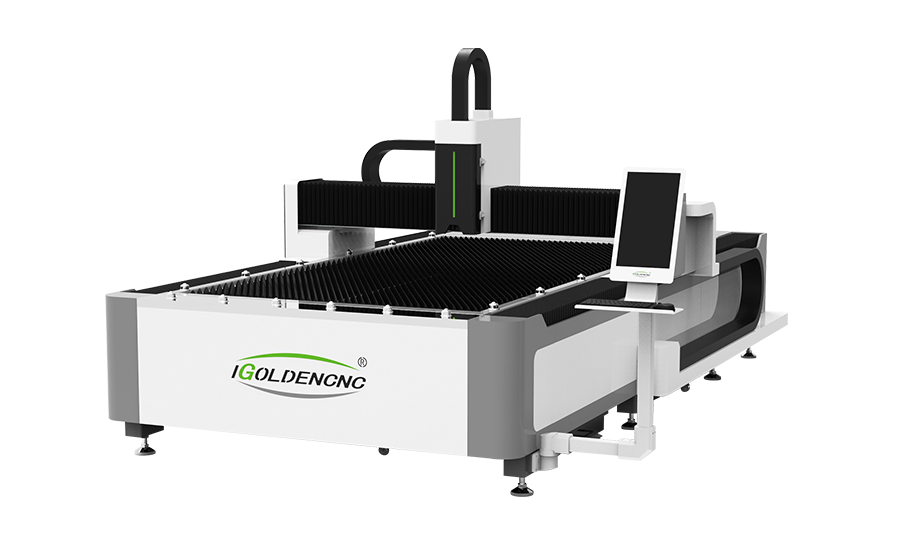

Igoldenlaser is a company that can provide suitable laser cutting solutions according to the accuracy requirements of the processed products and equipment budget. The main business includes: metal laser cutting machines, fiber laser cutting machines, laser pipe cutting machines, etc., dedicated to laser welding and cutting equipment and laser surfaces A high-tech enterprise engaged in the research and application of processing technology. Laser cutting machines are now mainly divided into CO2 lasers, YAG solid-state lasers and fiber laser cutting machines. These three lasers cutting machines have their own characteristics in production. Below, we will compare three common lasers from several aspects. The characteristics of the cutting machine.

1.Operational requirements and maintenance

The laser needs to adjust the optical path before use. The condition of the optical path will directly affect the cutting effect of the workpiece. Therefore, manual adjustment of the optical path and regular maintenance are required; the YAG solid-state laser has obvious thermal lens effect and requires frequent maintenance; fiber laser fiber transmission, adjustment-free, Maintenance-free, high stability, easy operation.

2. Cutting speed and effect

The cutting speed of fiber laser is 2-3 times that of CO2 laser of the same power. It has a particularly prominent advantage in the cutting process of metal sheets. It has excellent performance in the other two laser cutting machines, with good cutting quality, small gaps and neat edges.

3. Material suitability and application industry

Lasers are more widely applicable to materials, while the applicability of fiber lasers to metal materials, including high-reflective materials such as aluminum and copper, is more in line with the processing requirements of sheet metal manufacturing, 3C home appliance industry, and new energy industry.

4. Energy consumption and overall cost

The photoelectric conversion rate of fiber laser is more than 30%, the photoelectric conversion rate of the same power CO2 laser cutting machine is about 10%~15%, and the photoelectric conversion rate of solid laser is 3%. The power consumption of fiber laser is only 20-30% of the same power laser, and the overall cost is lower.

Through the comparison, it can be seen that the fiber laser cutting machine works more efficiently under the same conditions, the cutting effect is better, and it is maintenance-free, but the purchase cost is slightly higher. Large and medium-sized enterprises can give priority to fiber optic equipment.

评论

发表评论