Pipe laser cutting machine has the trend of metal tube processing

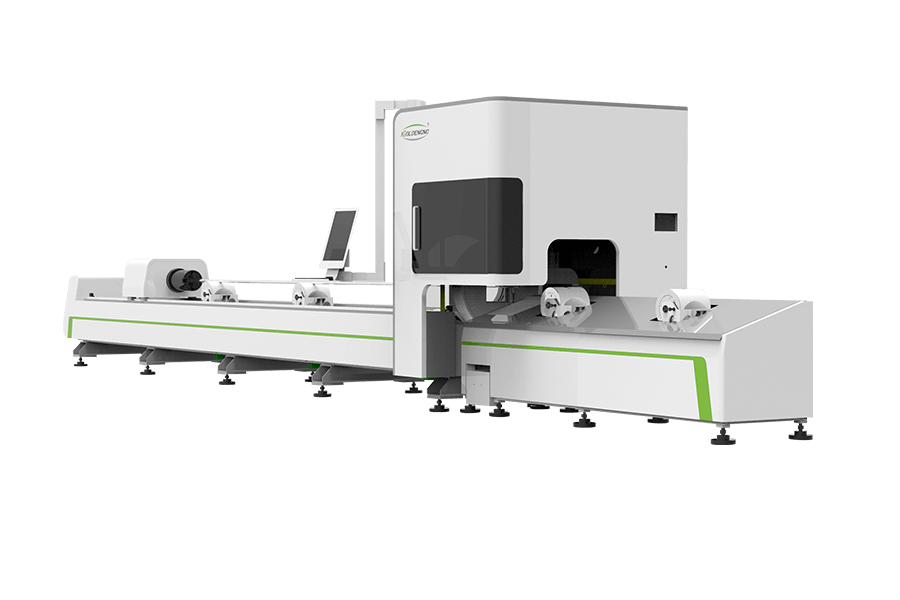

Laser pipe cutting machine is a special equipment that uses laser technology to cut various metal pipe fittings on pipe fittings and profiles. It is a high-tech industrial production equipment integrating CNC technology, laser cutting and precision machinery. It has the characteristics of professionalism, high speed, high precision, high efficiency, high-cost performance, low operation cost and good processing effect.

Under the condition of my country's strong technical strength, the cutting quality, effect and cost of the tube laser cutting machine have been greatly improved. Many industries have been widely used, the plane cutting, drilling, cutting, carving and other processes of the laser cutting machine are all the cutting needs of individual development. Through the computer control system, the computer can draw arbitrary graphics at will, and complete various complex and fancy pattern cutting, and the operation is simple.

Compared with the traditional cutting method, the pipe cutting machine not only has high speed and low consumption, but also has no mechanical stress on the pipe fittings, so the effect, accuracy and cutting speed of the cut products are very good, and it also has the characteristics of simple maintenance. In recent years, the tube laser cutting machine has developed very fast, and it has gradually replaced the traditional technology and has become a trend in the metal processing industry.

Due to the good processing advantages of pipe cutting machine processing, the processing cost has dropped significantly. At present, more and more hardware processing companies, bathroom manufacturing companies and auto parts processing companies are using tube laser cutting machines.

The tube laser cutting machine has the following advantages:

1. The cutting accuracy is high, and the dimensional accuracy is high. The cut is flat and clean, without burrs, and material loss is minimal;

2. The heat-affected zone of laser cutting is very small, there is almost no thermal deformation, and no oxidation can produce high-quality and more consistent parts, which is especially beneficial for subsequent automatic welding;

3. High cutting efficiency, mass production can be realized. All operations of laser cutting can be unified into the same unit as a continuous operation process, which greatly reduces logistics time. The standard pipe length is 6 meters, and the traditional processing method requires very heavy clamping, and laser processing can easily complete the clamping and positioning of several meters of pipe, which makes batch processing possible.

4. The laser cutting machine adopts digital system control, which is also one of the advantages of laser cutting machine cutting pipes. First of all, to ensure accuracy and flexibility, the laser tube cutting technology can process any shape that has been programmed, and it can be cut in any direction. The shape of the template can be changed quickly without the help of any tools. As long as the design plan can be modified at the last minute, without affecting the entire production process; the greater advantage is that the end user can control the production of short or medium versions instead of manufacturing a large number of templates, which can be faster Respond to customer needs in a timely manner, which provides the possibility to realize personalized customization.

With the continuous innovation and application of laser pipe cutting machine technology, in the future, more industries will use laser pipe cutting machines to promote production, maintain better competition, achieve long-term efficient and stable operation of equipment, and help the pipe processing industry increase efficiency and value-added .

评论

发表评论