4 X 8 CNC Router Machine:Premium Cutting and Carving

4 x 8 CNC router is a computer-controlled cutting machine designed for woodworking, plastics, and other materials. It has a working area of 4 feet by 8 feet (48 inches by 96 inches), which is a common size for many applications, including furniture making, sign production, and hobbyist projects. CNC routers use CAD/CAM software to create designs that are then translated into instructions for the machine to follow.

Here are some key features of a 4 x 8 CNC router:

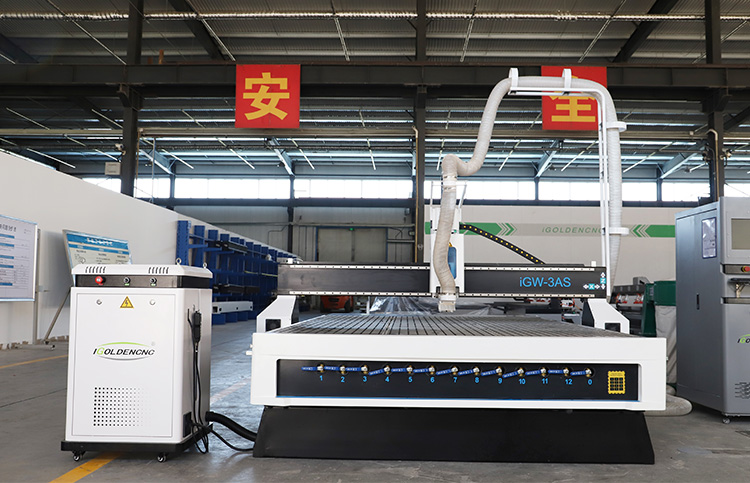

Table Size: The machine's table measures 4 feet wide by 8 feet long, allowing for the processing of large materials.

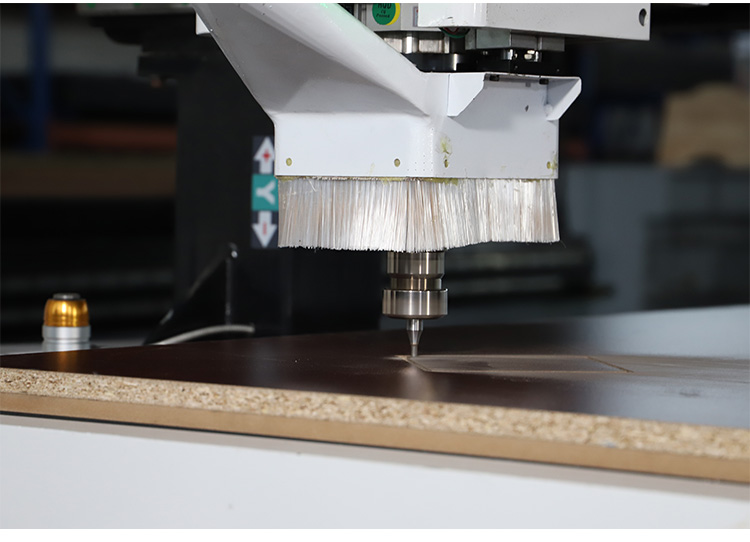

Spindle: The spindle is the cutting tool's motor, responsible for rotating the router bit. The power of the spindle can vary, with common options ranging from 1.5 kW to 5.5 kW. Higher power spindles can cut through denser materials more efficiently.

Router Bits: A variety of router bits can be used with a CNC router, depending on the material you're working with and the desired finish. Common bit materials include carbide and high-speed steel.

CAD/CAM Software: To create designs for a CNC router, you will need CAD/CAM software.

Control System: The control system is responsible for translating your design into instructions for the CNC router. Some common control systems include Mach3, UCCNC, and LinuxCNC.

Stepper Motors or Servo Motors: These motors control the movement of the router along the X, Y, and Z axes. Stepper motors are more common in hobbyist machines, while servo motors are more precise and used in industrial applications.

Linear Guides and Ball Screws: These components ensure smooth and precise movement along the axes. High-quality linear guides and ball screws are essential for accurate cutting.

Dust Collection: A built-in dust collection system helps keep your workspace clean and can prolong the life of your machine by reducing debris buildup.

Safety Features: Some CNC routers may include safety features such as emergency stop buttons, limit switches, and spindle guards to protect the operator and the machine.

To use a 4 x 8 CNC router, the material to be cut or carved is typically clamped to a table or bed that moves in the X and Y directions, while the cutting tool moves in the Z direction. The cutting tool can be a router bit, a drill bit, or a laser, depending on the material being worked with and the desired outcome.

The CNC router can be programmed to cut out parts with high precision and accuracy, making it ideal for use in industries such as woodworking, cabinetry, and metal fabrication. It is also commonly used in the production of signs, plaques, and decorative items.

Overall, a 4 x 8 CNC router is a versatile and powerful tool that can be used for a wide range of cutting and carving applications.

When selecting a 4 x 8 CNC router, consider your specific needs, such as the materials you plan to work with, your budget, and the desired level of precision and speed. There are many CNC router manufacturers and models available to suit a wide range of applications.

评论

发表评论