Laser Cut Acrylic

Laser cutting acrylic is a popular method for precision cutting and shaping acrylic sheets. It involves using a laser beam to melt or vaporize the acrylic material along a predetermined path, resulting in clean and precise cuts.Laser cutting acrylic is a precise and versatile process commonly used in various industries, including signage, displays, crafts, and manufacturing.

Laser cut acrylic has a wide range of applications. It is commonly used in industries such as signage, display fabrication, architectural models, jewelry making, prototyping, and more. Laser cutting acrylic can create intricate patterns, logos, letters, and shapes, making it a versatile option for various creative and industrial projects.

Laser Cut Acrylic

Acrylic, as a plastic polymer material, it involves many processing method such as acrylic cutting, acrylic engraving, acrylic marking and milling. At present, the acrylic cutting are mainly realized by laser machine or CNC router as the main CNC machines for the processing of acrylic products. And we will talk about the acrylic cutting and acrylic engraving projects made by our acrylic laser cutting machine(acrylic laser cutter) . The aluminum sheet processed by laser machine and CNC Router has high precision and owns beautiful patterns. It can provide shading and ventilation and also beautify buildings. Moreover, the hollow aluminum sheet can be 100% reusable, which is green and healthy.

Acrylic cutting and Acrylic engraving are widely used in shop windows, advertising lamp boxes, signboards, handicrafts, direction boards and display racks. And people can also find its application in bathroom facilities, fluorescent lamps, and suspended ceilings, screens, decorative lighting and floor decorations.

Laser Cut Acrylic Machines

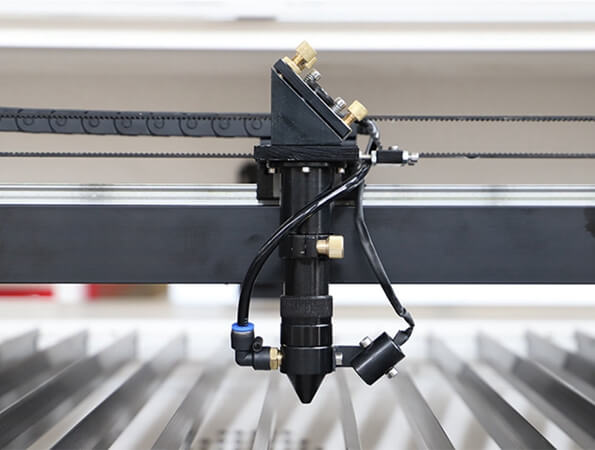

When laser cutting acrylic, it’s recommended to optimize cutting parameters based on the specific acrylic material and thickness. It’s also important to have a well-maintained laser machine and perform regular checks on the focal length, alignment, and cleanliness of the laser optics to ensure optimal cutting results.

Key Points About Laser Cutting Acrylic

Laser Cutting Process

Laser cutting acrylic involves focusing a high-powered laser beam onto the surface of the acrylic sheet. The laser beam heats the material, causing it to melt or vaporize along the cutting line. The focused laser beam provides a narrow kerf, resulting in precise cuts with minimal heat-affected zones.

Benefits of Laser Cutting Acrylic

Laser cutting acrylic offers several advantages. It provides high precision and accuracy, allowing for intricate designs and complex shapes. The process is fast and efficient, enabling rapid production and high repeatability. Laser cutting also produces smooth edges without the need for additional finishing, reducing post-processing requirements.

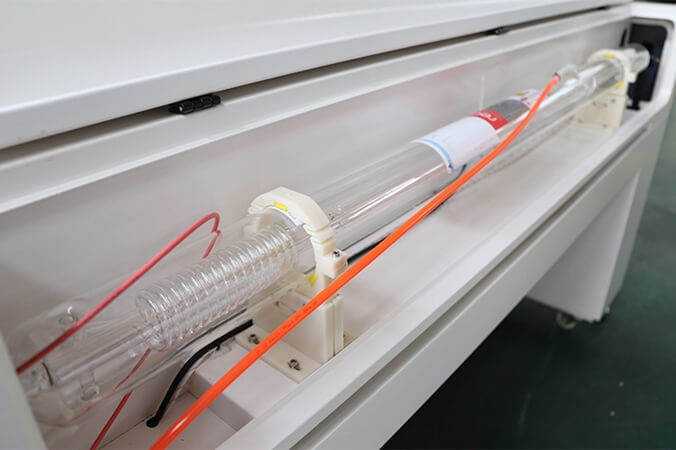

Type of Laser

CO2 lasers are commonly used for cutting acrylic due to their high power and ability to be absorbed by the material. These lasers emit a wavelength of around 10.6 micrometers, which is well-suited for acrylic cutting applications. Fiber lasers can also be used for thinner acrylic sheets or when high-speed cutting is required.

Material Considerations

Acrylic, also known as PMMA (polymethyl methacrylate), is a thermoplastic material widely used in various applications. Different types of acrylic sheets are available, including transparent, colored, and opaque varieties. The laser cutting process can be optimized for different acrylic thicknesses and types by adjusting the laser power, cutting speed, and focus.

Design Considerations:

Laser cutting allows for great design flexibility when working with acrylic. Intricate patterns, fine details, and complex shapes can be achieved with precision. However, it’s important to consider factors such as material thickness, kerf width (the width of material removed by the laser), and the need for support structures or tabs to prevent parts from falling out during cutting.

Safety Precautions

Laser cutting acrylic should be performed in a well-ventilated area or with the use of exhaust systems to remove fumes and gases generated during the process.

Safety goggles and appropriate personal protective equipment (PPE) should be worn to protect against laser radiation and potential debris. It’s important to follow safety guidelines and operating procedures provided by the laser machine manufacturer.

Post-Processing

Laser cutting acrylic often produces clean edges, reducing the need for extensive post-processing. However, some minor burrs or roughness may be present, particularly on thicker acrylic sheets. These can be removed through sanding or flame polishing to achieve a smooth and polished finish.

Laser Engraving Acrylic

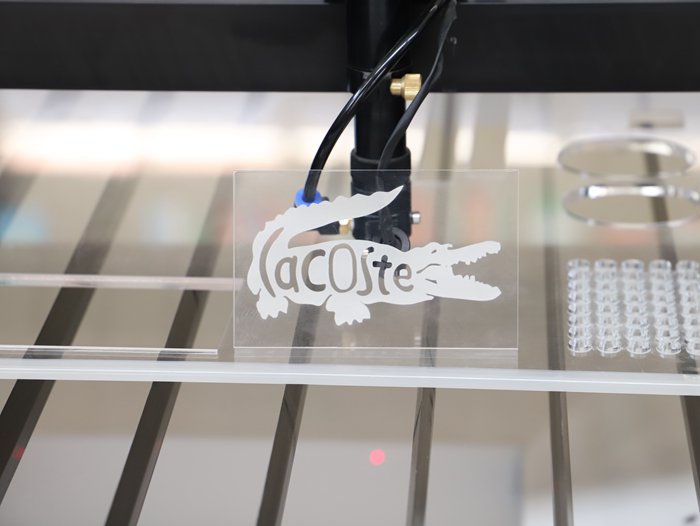

Laser engraving acrylic is a process that uses a laser beam to etch or mark the surface of acrylic material. The laser beam selectively removes or vaporizes the acrylic, creating permanent markings or designs.

Laser engraving acrylic involves using a focused laser beam to heat and vaporize the surface of the acrylic material. The laser removes a thin layer of the acrylic, creating a visible mark or engraving. The depth and intensity of the engraving can be controlled by adjusting the laser power and speed.

Laser engraving acrylic offers several advantages. It provides high precision and detail, allowing for intricate designs, text, logos, and graphics. The process is non-contact, which means there is no physical contact between the laser and the material, minimizing the risk of damage. Laser engraving is fast and efficient, enabling high-speed production with consistent and repeatable results.

Laser engraving allows for precise and intricate designs on acrylic. Vector-based design files, such as those created with software like Adobe Illustrator or CorelDRAW, are commonly used for laser engraving. The laser can etch text, logos, graphics, and even grayscale images onto the acrylic surface. It’s important to consider the size, resolution, and positioning of the design to achieve the desired engraving result.

CO2 lasers are commonly used for engraving acrylic due to their ability to be absorbed by the material.

These lasers emit a wavelength of around 10.6 micrometers, which is well-suited for acrylic engraving applications.

Fiber lasers can also be used for certain types of acrylic, particularly for surface marking or when high-speed engraving is required.

Overview of the Laser Cutting Process for Acrylic

1. Material Selection: Acrylic Type: Acrylic sheets come in various types, including cast and extruded acrylic. Cast acrylic is preferred for laser cutting due to its clarity and consistent thickness.

2. Design Preparation: Vector Design Software: Create or import your design into vector-based graphic design software like Adobe Illustrator or CorelDRAW. Vector files provide the necessary instructions for the laser cutter.

3. Material Securing: Laser Cutting Bed: Place the acrylic sheet on the laser cutting bed, ensuring it is securely held in place. Some machines have a vacuum table or other methods to keep the material flat and steady during cutting.

4. Machine Setup: Focus Adjustment: Set the focal length of the laser to match the thickness of the acrylic sheet. This ensures the laser beam is at its most concentrated point for optimal cutting. Power and Speed Settings: Adjust the laser power and cutting speed based on the type and thickness of the acrylic. This varies depending on the specific machine and manufacturer recommendations. Ventilation and Extraction: Proper ventilation is crucial to remove fumes and gases produced during the cutting process. Many laser cutters have built-in exhaust systems.

5. Laser Cutting: Path Execution: The laser cutter follows the vector path specified in the design file. The laser beam melts and vaporizes the acrylic along this path, creating the desired cut. Precision and Detail: Laser cutting provides high precision, allowing for intricate designs, sharp angles, and smooth edges. The quality of the cut depends on the power and speed settings, as well as the quality of the laser cutter.

6. Engraving (Optional): Additional Detailing: Laser cutters can also be used for engraving on the acrylic surface. This is often employed to add text, logos, or decorative elements.

7. Post-Processing: Cleaning: Once the laser cutting is complete, remove the cut acrylic pieces from the machine. Clean off any residue or debris left on the material during the cutting process.

8. Safety Measures: Protective Gear: Operators should wear appropriate protective gear, including safety glasses, to shield against laser exposure. Ventilation: Ensure proper ventilation in the workspace to manage fumes and gases generated during cutting.

9. Quality Control: Inspecting Cuts: Check the cut pieces for quality, ensuring that the edges are clean and the design is accurately executed.

10. Applications: Versatility: Laser-cut acrylic finds applications in a wide range of industries, including signage, displays, model making, architectural models, jewelry, and more.

评论

发表评论