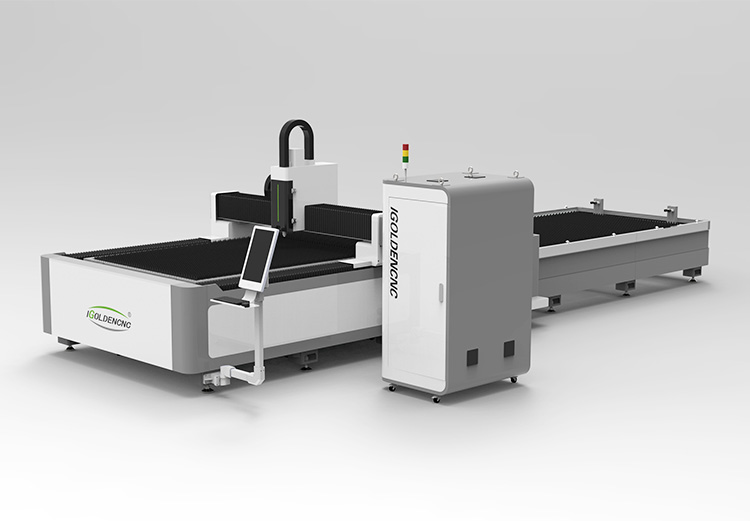

Industrial Laser Cutting Machine For Metal With Exchange Table

Metal Laser Cutting Machine

High Performance 1KW/2KW/3KW/4KW Fiber Laser Cutting Machine Sheet Metal Laser Cutter with Exchange Platform.

The exchange platform metal laser cutting machine is the first choice for large-scale mass production of sheet metal processing. Automatic loading and unloading saves more time. And the double working platform greatly reduces the time for loading and unloading and improves processing efficiency.

Exchange Platform Fiber Laser Cutting Machine for Steel, Iron advantages

1. With double platform, saving more than 50% of space and bring double production benefits.

2. The strong steel bed keeps you from not worrying about the cutting effect.

3. Aviation aluminum beams with the advantages of good integrity, rigidity, toughness and ductility, which ensure that the machine is running at 150m / min.

4. World brand guides, racks and other components, make you no longer worry about the precision of cutting.

Sheet metal cutters application

Fiber laser cutting machine with exchange platform, is the high efficiency cutting machine for metal sheet processing, the standard working area is 3000*1500mm, which can be widely used in stainless steel plate, carbon steel plate, aluminium plate, copper plate, and other metal plate, and can be equiped with 1000-6000w laser source for different thickness plate cutting.

Metal sheet fiber laser cutting machines are used in various metalworking industries. For example, aviation, aerospace, electronics, electrical appliances, automobiles, machinery, precision accessories, ships, metallurgical equipment, elevators, household appliances, craft gifts, tool processing, decoration, advertising, and other manufacturing and processing industries.

Fiber Laser Cutters

A fiber laser cutter is an automated metal cutting system that uses a CNC controller to drive the 1064nm laser beam from a fiber laser generator to move along the tool path generated by the CAD/CAM software to achieve the metal fabrication plans. It is a fine precision cutting system for both sheet metals and tubes. It can cut both flat and beveled metal shapes and profiles.

With a robotic arm, it can do 3D laser-cut jobs. It uses the non-contact cutting method of laser beam, which will not damage the substrate, and the thermal influence of the spot irradiation area is smaller. It can cut carbon steel, stainless steel, spring steel, silicon steel, aluminum, galvanized sheet, pickling sheet, gold, silver, titanium, copper, brass, and alloys. It is used for sheet metal fabrication, elevator manufacturing, electronic appliances, auto parts, machinery manufacturing, precision parts, marine aviation, metal crafts, and advertising.

评论

发表评论