Laser Welding Gun 3 In1 for Sale

A 3 in 1 laser welding cutting cleaning gun is a device that combines three laser processes: welding, cutting, and cleaning. This type of machine is designed to offer a wide range of capabilities and can perform multiple functions using different laser heads or nozzles.

Laser Welding Gun

The 3-in-1 laser welding gun is an advanced tool that significantly enhances productivity and quality in industrial applications. Its ability to perform welding, cutting, and cleaning with precision and efficiency makes it a valuable asset for various industries. When selecting a 3-in-1 laser welding gun, it’s important to consider the specific requirements of your applications, including material types, thicknesses, and desired outcomes, to ensure the best performance and return on investment.

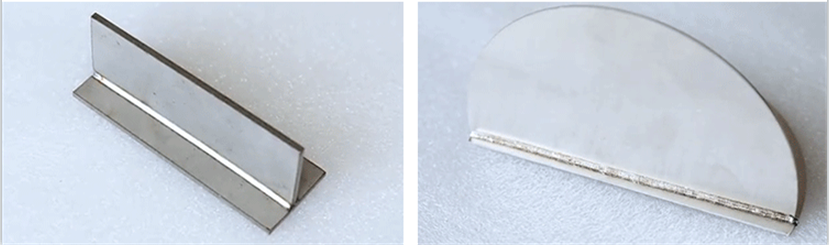

Laser welding involves using a high-powered laser beam to fuse two pieces of material together. This process is precise and produces a high-quality weld with minimal heat input, resulting in less distortion and less material damage.

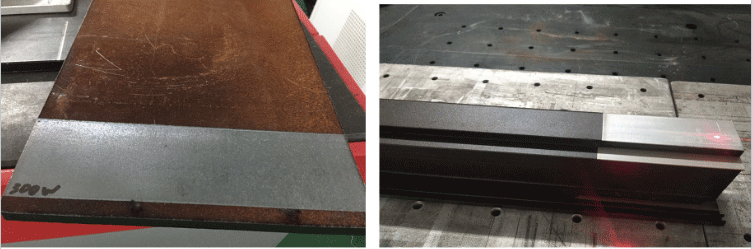

Laser cutting, on the other hand, involves using a laser beam to cut through materials such as metal, plastic, and wood. This process is highly accurate and can produce intricate cuts and shapes with ease.

Laser cleaning, as previously mentioned, involves using a laser beam to remove rust, paint, and other contaminants from a surface. This process is non-abrasive and can clean even the most delicate surfaces without damaging them.

Key Features and Functions

- Welding:

- Precision: Laser welding offers precise control over the welding process, resulting in clean and strong welds.

- Materials: Suitable for a wide range of materials, including stainless steel, carbon steel, aluminum, copper, and other alloys.

- Applications: Ideal for thin materials, intricate parts, and applications where traditional welding methods might struggle.

- Cutting:

- Accuracy: Laser cutting provides high precision, allowing for intricate shapes and designs to be cut with minimal heat-affected zones.

- Speed: Faster than many traditional cutting methods, increasing productivity.

- Versatility: Can cut a variety of materials, making it useful for multiple applications in manufacturing and fabrication.

- Cleaning:

- Non-contact: Laser cleaning is a non-abrasive and non-contact method, reducing the risk of damage to the base material.

- Efficiency: Effective at removing rust, paint, oxides, and other contaminants from surfaces.

- Environmentally Friendly: Does not use chemicals or abrasive materials, making it an eco-friendly cleaning solution.

3 in 1 laser welding gun or a 3 in 1 laser welding cutting cleaning machine

Handheld Laser Cleaning, Welding, Cutting Machine 3-in-1 Advantage

1.Lightweight and flexible, easy to operate, can meet the three-in-one welding / cleaning / cutting, no need to change the gun head;

2.Invite professional international laser friends to translate, can be customized in multiple languages;

3. The hand-held galvanometer swing head has the advantages of adjustable light spot, extreme lightness, first-class feel, and deeper melting depth, which can adapt to different scenarios of customers;

4.The hand-held welding head adopts the protective lens, the focusing lens and the collimating lens all adopt the drawer installation method, which is convenient for customers to repair and replace by themselves, and the temperature is constantly monitored;

5.The length of the control line is not limited, the longest is 1 km;

6.The product is designed with the concept of ergonomics, fully considering the applicability of the welding process and the comfort of long-term use (0.8KG), and has a safety lock that touches the mouth to contact the work light to prevent accidental injury to others;

7. The system monitors the running status from time to time, monitors and collects the running status of the laser, chiller, and control panel.

A 3 in 1 laser welding cutting cleaning machine applications:

- Automotive: The machine can be used in the automotive industry to clean, weld, and cut parts such as engine blocks, transmissions, and exhaust systems.

- Aerospace: The machine can be used in the aerospace industry to clean, weld, and cut aircraft parts such as turbine blades, fuel nozzles, and structural components.

- Manufacturing: The machine can be used in the manufacturing industry to weld, cut, and clean various parts and components, including sheet metal, pipes, and machinery parts.

- Construction: The machine can be used in the construction industry to weld, cut, and clean materials such as steel beams, concrete, and brickwork.

- Electronics: The machine can be used in the electronics industry to weld, cut, and clean components such as circuit boards, sensors, and connectors.

- Medical: The machine can be used in the medical industry to clean, weld, and cut surgical tools, medical devices, and implants.

- Jewelry: The machine can be used in the jewelry industry to weld and cut precious metals such as gold, silver, and platinum.

Overall, the 3 in 1 laser welding cutting cleaning machine is a versatile tool that can find applications in various industries, where precision, efficiency, and versatility are essential.

评论

发表评论