Affordable CNC Milling Machine Wood and Metal

In the realm of modern manufacturing, the CNC milling machine stands as a cornerstone of precision and efficiency. These machines have revolutionized the way we approach machining processes, offering unparalleled accuracy and the ability to produce complex parts with ease. Whether you’re a seasoned machinist or a newcomer to the field, understanding the intricacies of CNC milling machines can significantly enhance your manufacturing capabilities.

Affordable CNC Milling Machine

A CNC milling machine is a sophisticated and highly precise tool used to shape and cut materials like metal, wood, and plastic. These machines are widely used in manufacturing and prototyping due to their ability to produce complex shapes and high-quality finishes.

Equipment that uses computerized controls to operate and manipulate cutting tools to shape materials into desired forms. These machines are capable of performing a wide range of operations, including drilling, cutting, and milling, with high precision and repeatability.

Small CNC milling machines are compact, desktop-sized machines that offer a range of advanced milling capabilities in a space-efficient package. These machines are well-suited for prototyping, small-scale production, and educational/hobbyist use.

Key Features of Small CNC Milling Machines

Compact Size

Small CNC mills have a small footprint, often fitting on a desktop or workbench. This makes them ideal for use in limited workshop or studio spaces. Typical work envelopes range from around 8″ x 6″ x 3″ up to 15″ x 12″ x 5″.

High Precision

Despite their small size, these machines are capable of producing parts with tight tolerances and smooth surface finishes. They utilize high-quality components like ball screws, linear guides, and rigid frames to achieve this precision.

Versatile Machining

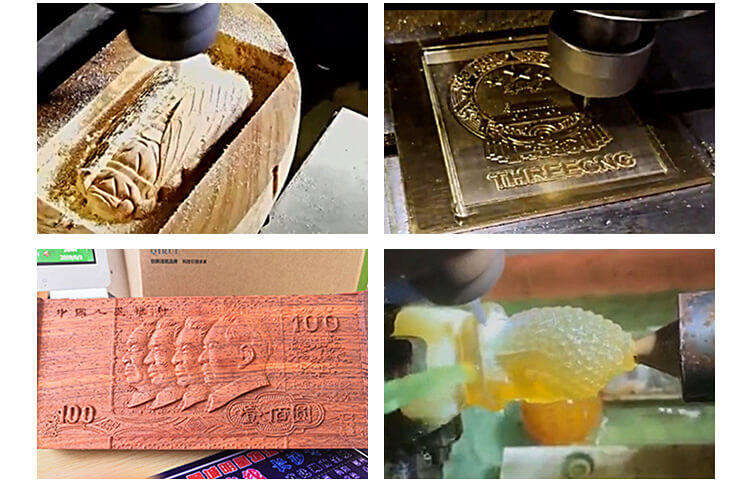

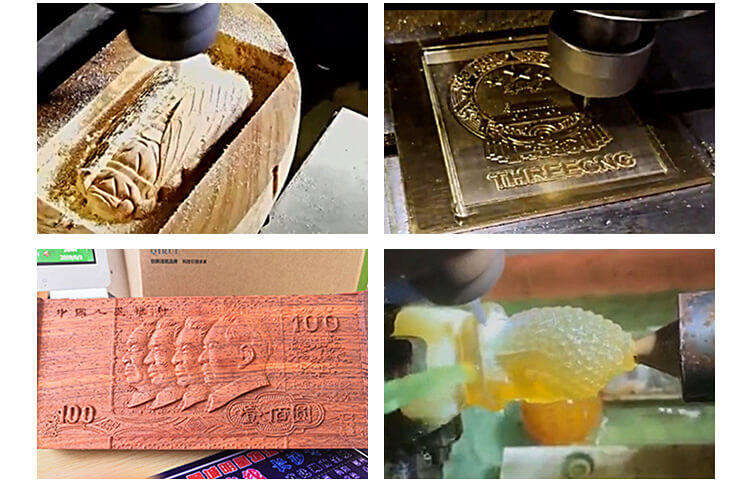

Small CNC mills can handle a variety of materials including wood, plastics, aluminum, and other soft metals. This versatility allows them to be used for prototyping, model making, and small-scale production across many industries.

User-Friendly Operation

Many small CNC mills are designed with ease of use in mind. They often feature intuitive control interfaces, automated tool changers, and integrated CAM software to simplify the machining process. This makes them accessible for hobbyists and small businesses.

Affordable Pricing

Compared to larger industrial CNC machines, small desktop models are much more affordable, making them accessible for individual users and small shops. Prices can range from a few thousand dollars up to around $10,000 for a well-equipped model.

Types of CNC Milling Machines

There are several types of CNC milling machines, each designed for specific applications and capabilities. Here are some of the most common types:

Vertical CNC Milling Machines

Vertical CNC milling machines have a vertically oriented spindle that holds the cutting tool. These machines are versatile and commonly used for a wide range of applications, from prototyping to production.

Horizontal CNC Milling Machines

Horizontal CNC milling machines have a horizontally oriented spindle. These machines are ideal for machining heavy and large parts, as they offer greater stability and support.

5-Axis CNC Milling Machine

5-axis CNC milling machines are capable of moving the cutting tool along five different axes simultaneously. This allows for the creation of highly complex and intricate parts, making these machines ideal for aerospace, automotive, and medical industries.

How Does a CNC Milling Machine Work?

The operation of a CNC milling machine involves several key steps:

- Design Creation: The first step is to create a digital design of the part using CAD (Computer-Aided Design) software. This design is then converted into a CNC program using CAM (Computer-Aided Manufacturing) software.

- Material Loading: The raw material, often referred to as the workpiece, is securely clamped onto the machine’s worktable.

- Tool Selection: The appropriate cutting tools are selected and loaded into the machine’s tool holder.

- Machining: The CNC program is executed, and the machine’s cutting tools follow the programmed path to shape the material into the desired form.

- Finishing: After machining, the part may undergo additional processes such as deburring, polishing, or coating to achieve the final finish.

Types of Materials

Desktop CNC machines are versatile and can process a wide range of materials, including:

- Wood: Commonly used in woodworking and carpentry.

- Plastics: Utilized in prototyping and product design.

- Metals: Employed in jewelry making, metalworking, and small-scale manufacturing.

- Composites: Applied in automotive, aerospace, and consumer goods.

- Foam: Used in packaging, modeling, and crafts.

Applications of CNC Milling Machines

Prototyping and Product Development

In the fields of prototyping and product development, desktop CNC machines are invaluable tools. Applications include:

- Rapid Prototyping: Creating functional prototypes quickly and accurately.

- Custom Parts: Producing custom components for various projects.

- Product Design: Testing and refining product designs before mass production.

Education and Training

Desktop CNC machines are widely used in educational institutions for teaching and training purposes. Applications include:

- Engineering Education: Providing hands-on experience with CNC technology.

- Vocational Training: Preparing students for careers in manufacturing and machining.

- STEM Programs: Enhancing science, technology, engineering, and mathematics education.

Choosing the Right CNC Milling Machine

When selecting a CNC milling machine, there are several factors to consider:

Machine Size

The size of the machine determines the maximum dimensions of the workpiece you can machine. Consider the types of projects you plan to work on and choose a machine with an appropriate work envelope.

Spindle Speed

The spindle speed affects the cutting performance and surface finish of the machined part. Machines with adjustable spindle speeds allow you to optimize the cutting conditions for different materials.

Tool Capacity

The tool capacity refers to the number of tools the machine can hold and automatically change during the machining process. A larger tool capacity allows for greater flexibility and efficiency in machining complex parts.

Software Compatibility

Ensure that the CNC milling machine is compatible with the CAD/CAM software you plan to use. Some machines come with proprietary software, while others are compatible with popular design programs like SolidWorks and Mastercam.

Ease of Use

If you’re new to CNC machining, look for a machine that is user-friendly and comes with comprehensive instructions and support. Many manufacturers offer online tutorials and customer support to help you get started.

Frequently Asked Questions (FAQ)

What materials can a CNC milling machine work with?

CNC milling machines can work with a wide range of materials, including metals (such as aluminum, steel, and titanium), plastics, composites, and wood.

How do I create a CNC program for my design?

CNC programs are created using CAM software, which converts the digital design from CAD software into machine-readable code. This code is then uploaded to the CNC milling machine for execution.

Can I use a CNC milling machine for prototyping?

Yes, CNC milling machines are commonly used for prototyping due to their ability to quickly and accurately produce parts with complex geometries.

How do I maintain my CNC milling machine?

Regular maintenance includes cleaning the machine, checking and replacing cutting tools, calibrating the machine, and ensuring the software is up to date. Refer to the manufacturer’s instructions for specific maintenance guidelines.

What is the difference between a vertical and a horizontal CNC milling machine?

Vertical CNC milling machines have a vertically oriented spindle, making them versatile and suitable for a wide range of applications. Horizontal CNC milling machines have a horizontally oriented spindle, offering greater stability and support for machining heavy and large parts.

评论

发表评论