Types of CNC Marble Granite and Quartz Machine

The CNC Marble Machine represents a fusion of technology and artistry, enabling craftsmen to transform raw marble into intricate designs and sculptures with unparalleled precision. These machines have revolutionized the stone industry, offering efficiency and accuracy in marble processing.

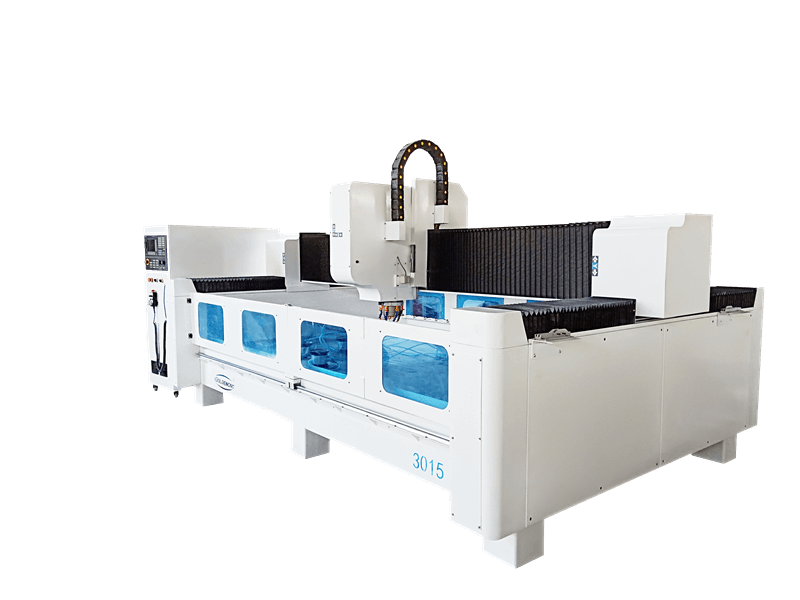

CNC Marble Granite and Quartz Machine

Granite CNC machine can be divided into different types in terms of function & structure, some of them are discussed here as follows:

CNC Stone Engraving Machine

Stone engraving machine, also known as stone cnc router, granite engraving machine, is a highly automatic CNC machine tool which takes tool bits for carving & engraving works on different materials, including marble, granite, quartz, bluestone, jade, artificial stone and ceramic, glass, plastic and other hard materials.

The CNC granite engraving machine can carry out various complicated works, such as linear carving, character carving, 2D flat engraving, 3D relieving, shadow carving, cutting, chamfering, drilling, etc.

CNC Stone Machining Center

The quartz stone CNC machining center is a dedicated stone processing equipment integrating shape-molding, edge polishing, engraving, milling and profile cutting. It successfully solves the problem of low working efficiency, high cost and poor performance during the production of of high-end process quartz stone countertops.

The stone CNC machining center is suitable for carving & edge polishing of cabinet stone countertops, tea tray & quartz stone countertops, and drilling, polishing, chamfering & engraving of other heterogeneous stone, ceramics, glass and microcrystalline.

Stone CNC Bridge Saw

CNC bridge saw is an advanced CNC cutting machine, it takes diamond blade as cutting tool and is controlled by 5-axis linkage system, namely, 3 straight moving axes and 2 rotation axes.

Different processing functions are available including cutting, polishing, drilling, engraving, etc. The CNC bridge saw has much advantages of high automation, easy operation and advanced functions, it greatly improves the working efficiency and processing accuracy, thus is an indispensable equipment for stone processing industry.

Key Features

- Precision Cutting and Carving: Achieves intricate designs with exceptional accuracy.

- Versatile Tooling Options: Equipped with a range of tools for different tasks.

- Automated Operation: Reduces manual labor and increases efficiency.

- Advanced Software Integration: Enhances design capabilities and processing precision.

- Robust Construction: Built to handle the demands of stone processing.

Applications of CNC Stone Machines

Architecture and Construction

In architecture and construction, CNC stone machines are used to create custom stone components, such as columns, facades, and flooring. The precision and speed of these machines make them ideal for producing high-quality building materials.

Art and Sculpture

For artists and sculptors, the ability to carve intricate shapes and designs is crucial. CNC stone machines can produce detailed sculptures and art pieces with ease, enhancing creativity and artistic expression.

Interior Design

In the interior design industry, CNC stone machines are used to create custom stone features, such as countertops, fireplaces, and decorative elements. The versatility and precision of these machines make them invaluable tools for designers and architects.

Monument and Memorial Production

In the production of monuments and memorials, these machines are used to engrave and shape stone with precision. The accuracy and efficiency of CNC stone machines ensure that these important pieces are crafted to the highest standards.

Advantages of CNC Stone Machines

Precision and Accuracy

CNC stone machines offer unparalleled precision, making them ideal for intricate designs and detailed carvings. The computer-controlled system ensures that every cut and engraving is consistent and accurate, reducing material waste and improving overall quality.

Versatility

These machines can handle a variety of stone materials, including granite, marble, limestone, and more. This versatility makes them suitable for various industries, from architecture to art and design.

Efficiency and Speed

With automated processes and high-speed operation, CNC stone machines significantly enhance productivity. They can complete complex processing tasks in a fraction of the time it would take using manual methods.

Artistic Expression

The precision and versatility of CNC stone machines open up new possibilities for artistic expression. Artists and designers can create intricate sculptures, engravings, and patterns that were previously difficult or impossible to achieve by hand.

CNC Marble Granite and Quartz Machine Cost & Price

The cost of marble CNC machine is closely related to the actual machine type and its configuration.

Different kinds of granite CNC machines are available such as marble engraving machine, stone cnc machining center, 5 axis cnc bridge saw, etc. Though of similar appearance, their functions & structures vary much.

Also, the actual configuration of those granite cnc machines are quite different, important parts that matter include HSD spindle, servo motors, drivers, CNC system, software, guide rails, rack pinon, etc.

Besides, some other factors will have to be taken into consideration for overseas buyers, including tax, customs clearance, shipping fee, etc. In general, market price of the marble cnc machine ranges from $ 5,000 to $ 100,000, depending on the actual type and the specific configuration of the marble machines.

1. What materials can a CNC stone machine handle?

These machines can handle a variety of stone materials, including granite, marble, limestone, and more. Their versatility makes them suitable for various industries and applications.

2. How does a CNC stone machine differ from traditional stone processing methods?

A CNC stone machine uses computer-controlled technology to process stone with precision and efficiency, while traditional methods rely on manual labor and tools. The machining center offers greater accuracy, speed, and versatility.

3. What are the benefits of using a CNC stone machine?

The benefits include precision processing, versatility, efficiency, artistic expression, and the ability to handle a variety of stone materials. These advantages make CNC stone machines a valuable tool for many industries.

4. How do I maintain a CNC stone machine?

Regular cleaning, routine inspections, tool maintenance, and software updates are essential for maintaining optimal performance. Proper care ensures the machine operates efficiently and extends its lifespan.

5. What are the future trends in CNC stone technology?

Future trends include increased automation, the ability to work with advanced materials, and the development of eco-friendly solutions. These advancements aim to enhance efficiency, versatility, and sustainability in stone processing.

Conclusion

The CNC Stone Machine is a powerful tool that offers precision, versatility, and efficiency in stone processing. Its ability to handle a wide range of stone materials makes it suitable for various industries, from architecture to art and design. By understanding the features, benefits, and maintenance requirements of these machines, businesses and artisans can optimize their processing operations and achieve superior results in their creative endeavors. As technology continues to evolve, CNC stone machines are poised to play an increasingly important role in modern manufacturing and design.

评论

发表评论