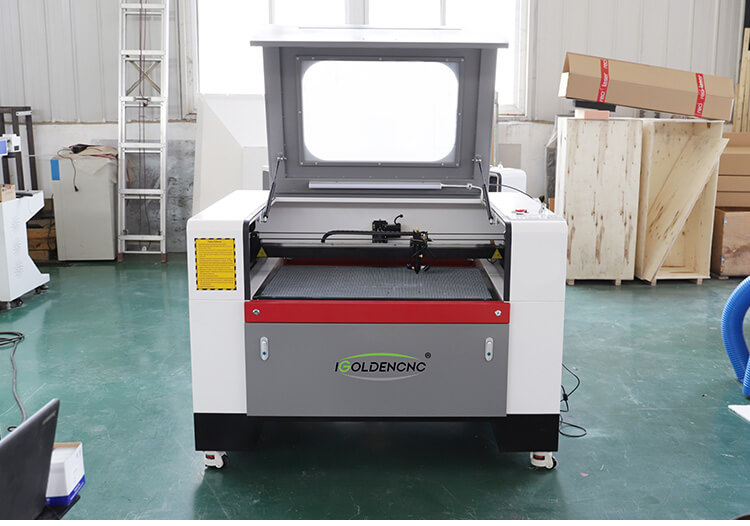

Acrylic MDF Plastic Fabric Laser Engraving Cutting Machine

Acrylic MDF Plastic Fabric Laser Engraving Cutting Machine

laser engraving cutting machine is devoted to the use of small processing sites, a small area of the laser cutting machine, laser cutting machine of a popular devices, called small laser cutting is irradiated with a laser beam to the release of the workpiece surface energy to enable the workpiece to melting and evaporation, in order to achieve the purpose of cutting and carving, has the advantages of high precision, fast cutting, not limited to cutting restriction pattern, save material automatic typesetting, incision smooth, low processing cost characteristics will gradually improve or to replace the conventional cutting process equipment.

Laser Engraving Cutting Machine

Laser engraving cutting machine use a high-powered laser beam, typically a CO2 laser or a fiber laser, to perform the engraving and cutting processes. The laser beam is focused through a series of mirrors and lenses to accurately heat and vaporize or burn away material, resulting in precise engravings or cuts.

Laser engraving cutting machine offer both engraving and cutting functionalities. Engraving involves creating designs, text, or images on the surface of a material by removing a thin layer of the material. Cutting, on the other hand, involves completely severing or separating the material along a specified path to create shapes or intricate patterns.

Laser engraving cutting machines are typically controlled using specialized software that allows users to import designs, adjust settings, and control the engraving or cutting process. The software often provides features like image editing, vectorization, and the ability to control laser power, speed, and depth.

Laser engraving cutting machine are known for their high precision and versatility. They can create intricate designs with fine details, sharp edges, and smooth curves. The ability to switch between engraving and cutting modes makes them suitable for a wide range of applications, including signage, awards, personalized gifts, prototyping, model making, and more.

The benefits of Laser engraving cutting machine

- Clean and perfect cuts – No post-processing necessary.

- High precision – Perfectly accurate laser cutting.

- High flexibility for cutting any shapes and sizes No tool wear.

- Consistent high cutting quality.

- No forces acting on the material means no mechanical stresses.

- Highly cost-efficient production from small batches up to medium sized serial production.

Laser Engraving Cutting Machine Applicable Industry

1. Creation: engraving patterns and words such as wood, bamboo, Ivory, bone, leather, marble, shell.

2. Advertising industry: mainly used in large character cutting, color plate engraving and cutting, advertising materials, crystal characters, easel, packing boxes.

3. Clothing and decoration industry: marking and cutting complex patterns on synthetic leather, woolens, clothing ,furnishing, glove, handbag and model, etc.

Laser Engraving Cutting Machine Applicable Material

Woodwork, paper, leather, cloth, organic glass, resin, acrylic, woolens, plastic, rubber, ceramic, crystal, jade, bamboo and other non-metal materials.

CO2 Laser Cutting Machine for Precise Cutting and Engraving

IGOLDENLASER offers CO2 laser cutting machines that are ideal for engraving designs in different materials such as thin woods, acrylics, and more. It can cut and engrave designs accurately at a fast speed. We also offer CO2 laser cutters with power options ranging from 60W to 300W.

Our machines can provide up to ±0.01mm locating accuracy. Rest assured that our CO2 cutters can provide up to 6,00mm/s cutting speed. It also provides up to 1,000mm/s engraving speed. Therefore, you can assure precise engraving at a fast speed.

CO2 Laser Cutting Machine Function

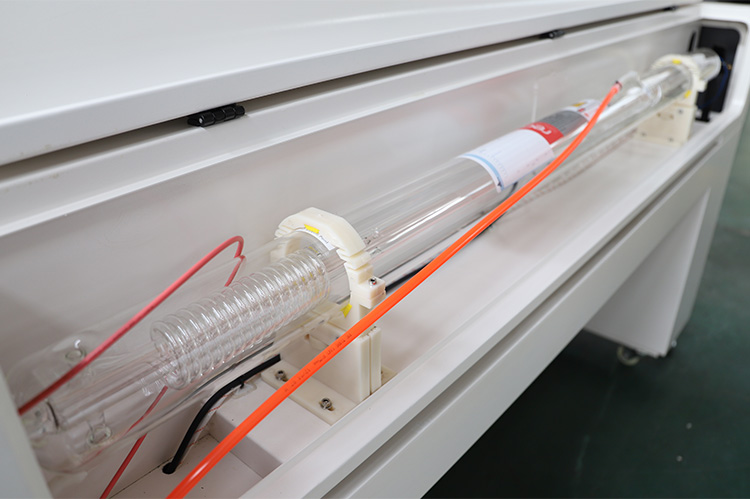

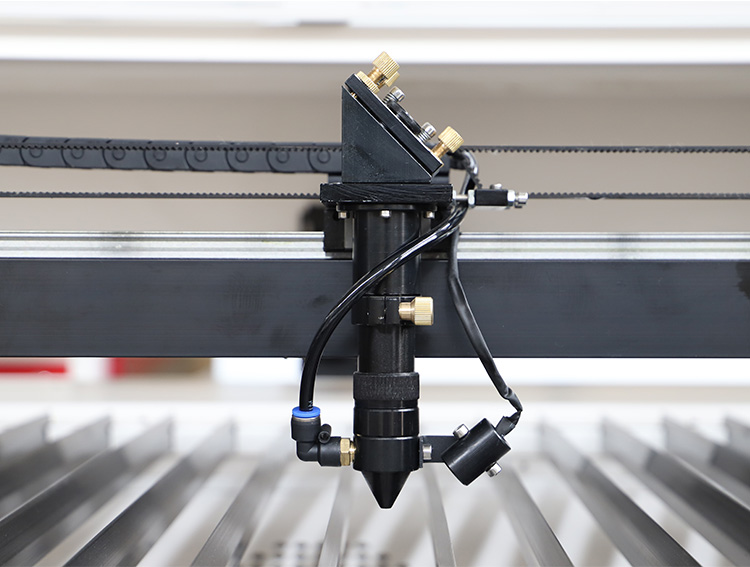

Our CO2 laser cutters are manufactured with two major units. One unit is for controlling which the energy source is located and the other is for laser-shooting. The Co2 laser medium is protected by sealed glass. The laser medium will produce a laser beam that will travel into the laser head with the assistance of reflective mirrors and a focusing lens.

The depth of the cutting produced by the machine will depend on the amplification lens and photon density. Our CO2 laser cutting machines are manufactured with higher and stabler frequency to assure high performance.

Why Choose IGOLDENLASER CO2 Laser Cutting Machine

Extensive Applications

We can supply CO2 laser cutters that are widely used for different industries such as advertisement, merchandising, art craft and gift, apparel, bag and shoe, home textile, toy, plastic industries, decoration, and more.

High Performance

You can assure that all our CO2 cutting machine can provide high performance, high efficiency, smooth cutting effect, and fast speed for non-metal cutting.

Multi-Functional

Aside from cutting, our CO2 laser cutting machines can also perform different functions such as marking and engraving to offer you a one-stop solution.

Precise Cutting

CO2 laser cutting machines are manufactured with a precise cutting solutions such as non-stop cutting, color separating cutting, and imitative cutting.

Different Cutting Designs and Types

IGOLDENLASER offers CO2 laser cutting machines that can provide the following cutting types and designs.

- Acrylic cutting/engraving

- Wood/Plywood cutting/engraving

- Double color plate engraving

- Plastic and vinyl cutting

- Paper cutting

- Fabric cutting

- PU cutting/engraving

We can also customize cutting designs according to your requirements.

What is CO2 Laser, CO2 Laser Tube, and CO2 Laser Generator?

The CO2 laser cutter adopts CO2 laser source (CO2 laser cutting technology) to cut and engrave non metals and soft metals. Therefore, some people also call it dual use CO2 laser cutting machine or mixed laser cutting machine. And it is consisted of various CO2 laser kits, such as laser generator, laser cutting head, laser cutter frame, laser cutting system, laser lens, laser mirror, laser power supply, water chiller, air compressor, and other many CO2 laser CNC kits.

CO2 laser machine usually uses CO2 gas to process non-metal materials such as wood, paper, leather, cloth, epoxy resin, acrylic, wool, plastic, rubber, ceramic tile, crystal, jade, bamboo, etc. While the auxiliary gases include nitrogen, helium, xenon, and hydrogen is also permitted. Since CNC CO2 laser has high energy conversion efficiency of up to 25% and good stability, it can also cut some thin metal materials such as aluminum and brass. In addition, the CO2 laser power is optional. So you can choose a 40W CO2 laser cutter for sale, 50W wood laser machine, 60W acrylic laser cutting machine, 80W CO2 laser cutting and engraving machine, 100W laser engraver, 130W CNC CO2 laser cutting machine, 150W CO2 laser cutter, 300W wood cutting laser cutter, etc.

评论

发表评论