Best 5 Axis Woodworking CNC Router for Sale

A 5-axis woodworking CNC router is a specialized computer-controlled machine designed for precision woodworking applications that require complex, three-dimensional cutting and shaping. These machines offer enhanced flexibility and precision by allowing the cutting tool to move in five different axes: X, Y, Z, and two rotational axes, typically referred to as A and B.

IGOLDENCNC offers a range of 5-axis CNC routers designed specifically for woodworking applications. Their machines are known for their precision, reliability, and advanced features.

How choosing a 5-axis CNC router for woodworking?

When looking for a 5-axis woodworking CNC router, consider factors such as machine size, spindle power, software compatibility, and budget. Additionally, it’s essential to review the specifications of various models and consult with manufacturers or distributors to find the machine that best suits your specific woodworking needs.

- Machine Size: Consider the size of the machine’s work envelope to ensure it can accommodate the size of the woodworking projects you typically work on.

- Precision and Accuracy: Look for a machine with high precision and accuracy to achieve the level of detail and quality you need in your woodworking projects.

- Speed and Efficiency: Evaluate the machine’s speed and efficiency to determine how quickly it can complete tasks without sacrificing quality.

- Software Compatibility: Ensure that the machine is compatible with the CAD/CAM software you plan to use for design and toolpath generation.

- Tool Changer: An automatic tool changer (ATC) can improve productivity by allowing the machine to change cutting tools automatically during the machining process.

- Spindle Power: The spindle’s power and speed should match the type of woodworking you do. Different projects may require different spindle capabilities.

- Dust Collection System: A built-in dust collection system can help maintain a clean work environment and prolong the life of the machine.

- Price and Budget: Determine your budget and find a machine that offers the best features within that budget. Keep in mind that 5-axis CNC routers can vary widely in price.

- Brand and Support: Consider purchasing from reputable manufacturers or suppliers that offer good customer support and service.

- Reviews and Recommendations: Seek out reviews and recommendations from other woodworking professionals or hobbyists who have experience with 5-axis CNC routers.

- Warranty and Maintenance: Inquire about the warranty and maintenance requirements to ensure long-term reliability and support.

Application of 5 Axis Woodworking CNC Router

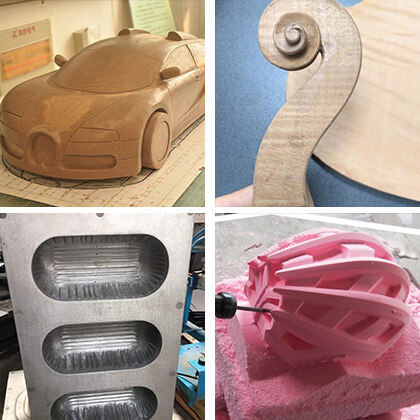

5 Axis CNC Router Machine, also known as five-axis machining center, 5 axis CNC mill machine, 5 axis CNC router center, etc., has the advantage of high machining accuracy and is specially used for machining complex curved workpieces. It is the most advanced CNC engraving machine in the world, and it has been applied to more and more industries. One-time clamping of the workpiece can complete complex processing requirements and can be adapted to the processing of modern molds such as auto parts and aircraft structures. There is a big difference between a five-axis machining center and a five-axis machining center. Many people do not know this and mistake the five-axis machining center as a five-axis machining center. The five-axis machining center has five machining axes X, Y, Z, A, and C. The X, Y, and Z axes and the A and C axes form a five-axis linkage processing. It is good at space surface processing, special-shaped processing, hollow processing, and drilling. Inclined holes, bevel cuts, etc.; while the pentahedron processing equipment side is similar to a three-axis machining center. Although it can process 5 faces at the same time, it cannot do special-shaped processing, beveled holes, cut bevels, etc.

1. Machinery manufacturing: Because of the high processing accuracy and large processing area of 5 axis CNC routers, it is very popular in the field of large-scale machining, such as the production of aircraft parts, automobile engines, and automobile gearboxes.

2. Mold manufacturing: Because the 5 axis CNC mill can process workpieces in 5 directions, it can almost produce a variety of molds, and it will not be impossible to process because the mold is three-dimensional.

3. Furniture manufacturing: the 5 axis wood CNC machine can realize multiple batches of repeated processing of furniture, and can process large wood at one time to maintain the integrity of the furniture. Improve furniture production efficiency and quality.

4.3D processing industry: Now more and more 3D processing industries choose to use 5 axis CNC router machines to realize 3D processing of workpieces, which can not only process various 3D workpieces quickly but also mass production.

In addition to the above fields, the 5 axis CNC router can also be used in the military industry, scientific research, precision machining, and medical fields. It is currently the most effective method for processing impellers, blades, marine propellers, large diesel engine crankshafts, etc. It plays an important role in the military industry, scientific research, precision equipment, high-precision medical, and other fields.

评论

发表评论