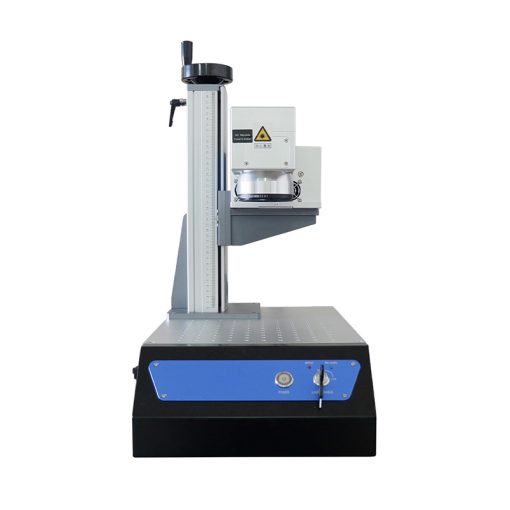

Laser Marking Machine for Metal

Laser marking and engraving machines have revolutionized the way we mark and engrave metals, offering unparalleled precision, speed, and versatility. These machines use a focused laser beam to create permanent marks on metal surfaces, making them ideal for various applications, from industrial manufacturing to jewelry design. In this comprehensive guide, we will explore the different types of laser marking machines for metal, their features, benefits, and applications.

Laser Marking Machine for Metal

A laser marking and engraving machine uses a high-energy laser beam to create permanent marks on the surface of a material. The laser beam interacts with the material, causing a change in its properties, such as color, texture, or reflectivity. This process can be used to create text, logos, barcodes, serial numbers, and other intricate designs on metal surfaces.

Laser marking machines for metal offer exceptional precision, speed, and versatility, making them an ideal choice for various industries and applications. Whether you are involved in industrial manufacturing, automotive, medical devices, electronics, or jewelry, a laser marking machine can enhance the quality and efficiency of your metal marking projects. By understanding the different types of laser marking machines and their benefits, you can make an informed decision and choose the right machine for your needs.

Applications of Laser Marking Machines for Metal

Some applications of fiber laser Engraving include:

- Product identification (e.g. date coding, batch numbers)

- Logo and graphics printing

- Security features (e.g. track and trace markings, counterfeit deterrents)

- 2D barcodes

- Data matrix codes

- QR codes

Industrial Manufacturing

In industrial manufacturing, laser marking machines are used for marking parts and components with serial numbers, barcodes, logos, and other identification marks. This helps in tracking and traceability, ensuring the quality and authenticity of the products.

Automotive Industry

The automotive industry relies on laser marking for marking engine parts, chassis components, and other critical parts. The high precision and durability of laser marks ensure the reliability and safety of the vehicles.

Medical Devices

Laser marking is widely used in the production of medical devices, including surgical instruments, implants, and diagnostic equipment. The precision and cleanliness of laser marks are crucial for meeting the stringent quality standards of the medical industry.

Electronics

In the electronics industry, laser marking is used for marking circuit boards, connectors, and other delicate components. The precision and minimal heat input of laser marking prevent damage to sensitive electronic components.

Jewelry

Laser marking is also used in the jewelry industry for engraving intricate designs, logos, and personalizations on metal pieces. The precision and control of laser marking allow jewelers to create detailed and high-quality marks without damaging the surrounding materials.

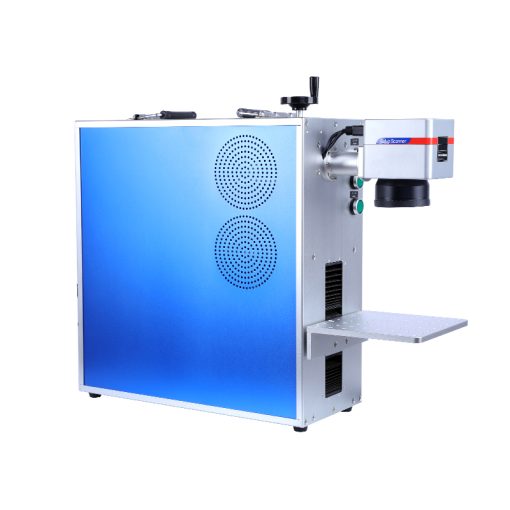

Types of Laser Marking Machines for Metal

Fiber Laser Marking Machines

Fiber laser marking machines are the most commonly used type for metal marking. They use a fiber optic cable to deliver the laser beam, providing high precision and efficiency.

- Advantages:

- High marking speed

- Excellent beam quality

- Low maintenance

- Long lifespan

- Applications:

- Industrial manufacturing

- Electronics

- Automotive parts

- Medical devices

CO2 Laser Marking Machines

CO2 laser marking machines use a gas mixture to generate the laser beam. While they are primarily used for marking non-metal materials, they can also be used for certain metal marking applications.

- Advantages:

- Versatile

- Suitable for marking organic materials

- Cost-effective

- Applications:

- Wood

- Plastics

- Glass

- Leather

UV Laser Marking Machines

UV (Ultraviolet) laser marking machines use a UV laser source with a short wavelength.

UV lasers are ideal for marking delicate and heat-sensitive materials, as they produce minimal heat during the marking process. They can create high-contrast marks on metals and other materials without causing damage or distortion. UV lasers are commonly used in the electronics, medical, and aerospace industries.

Advantages of Fiber Laser Marking Technology

Precision and Accuracy

Laser marking and engraving machines offer unparalleled precision and accuracy. Traditional marking and engraving methods, such as stamping or etching, can lead to inconsistencies and errors. Laser technology, however, allows for highly detailed and precise markings, ensuring consistency and quality. This level of precision is crucial for applications where accuracy is paramount, such as in the aerospace, medical, and electronics industries.

Non-Contact Process

Laser marking is a non-contact process, meaning the laser beam does not physically touch the metal surface. This eliminates the risk of damaging or distorting the material, which can occur with mechanical marking methods. The non-contact nature of laser marking also reduces wear and tear on the machine, extending its lifespan and reducing maintenance costs. ### Permanent and Durable Marks Laser marks and engravings are permanent and highly durable. They can withstand harsh environmental conditions, including exposure to chemicals, heat, and abrasion. This durability ensures that the marks remain legible and intact throughout the product’s lifecycle, making laser marking ideal for applications requiring long-lasting identification and traceability.

High-Speed and Efficiency

Laser marking and engraving machines operate at high speeds, significantly increasing productivity. They can quickly create detailed and complex designs, reducing production time. The automation capabilities of laser machines further enhance efficiency, allowing for continuous and unattended operation. This is especially beneficial for high-volume production environments.

Versatility

Laser marking and engraving machines are highly versatile and can work with a wide range of metals, including stainless steel, aluminum, brass, copper, titanium, and more. They can also mark and engrave various shapes and sizes, from flat surfaces to cylindrical objects. This versatility makes laser machines suitable for diverse applications across different industries.

Minimal Material Waste

Laser marking is a precise and controlled process, resulting in minimal material waste. Unlike mechanical methods that may require additional finishing or cleaning steps, laser marking produces clean and sharp marks without generating debris or residues. This contributes to cost savings and a more environmentally friendly manufacturing process.

Customization and Flexibility

Laser marking and engraving machines offer unparalleled customization and flexibility. Users can easily modify designs and create custom marks and engravings tailored to specific requirements. The ability to quickly change marking parameters and patterns allows for the production of unique and personalized items, catering to individual customer needs.

Fiber Lasers vs. Traditional Marking

Fiber lasers have transformed the engraving process and made it multiple times better. Let’s compare some of the traditional marking techniques with a fiber laser.

Inkjet marking Ink Jet vs Fiber Laser Marking

Inkjet marking uses ink to mark text, numbers, bar codes, etc. It’s functional, but the markings are susceptible to fading and water damage since it uses water-based ink. Fiber lasers provide a much more permanent and long-lasting solution.

Electrochemical Etch vs Fiber Laser Marking

Electrochemical Etching requires carefully cut felts, a marking head, a conductive net, and an electrolyte for marking slows down the overall process. Also, the process is manual, which isn’t suitable for automation. Fiber lasers are a hassle-free and much faster alternative.

Dot Peen vs Fiber Laser Marking

Dot Peen is loud, slow, and less precise. They can’t even engrave bar codes. On the contrary, lasers can engrave various materials and aren’t limited by complexity. Dot peen also has a higher operational cost.

Features of Laser Marking and Engraving Machines for Metal

High-Power Laser Sources

The laser source is a critical component of a laser marking machine. High-power laser sources, such as fiber lasers, are commonly used for metal marking and engraving. Fiber lasers offer excellent beam quality, high efficiency, and long operational life. They can generate intense laser beams that can penetrate and mark various metals with precision.

Advanced Control Systems

Laser marking and engraving machines are equipped with advanced control systems that manage the laser parameters and motion control. These systems often include user-friendly interfaces, allowing operators to input parameters, design patterns, and monitor the marking process. Some machines feature touchscreen displays and software integration for enhanced convenience and control.

Galvanometer Scanners

Galvanometer scanners, also known as galvo scanners, are used to direct the laser beam with high speed and accuracy. These scanners consist of two mirrors that move rapidly to position the laser beam on the metal surface. Galvo scanners enable fast and precise marking, making them ideal for applications requiring high-speed production and intricate designs.

Adjustable Focus

Adjustable focus is an important feature in laser marking and engraving machines. It allows users to adjust the focal length of the laser beam to achieve optimal marking results. Proper focus ensures that the laser beam is precisely concentrated on the metal surface, resulting in clear and sharp marks. Some machines feature automatic focus adjustment for added convenience.

Cooling Systems

Laser marking and engraving machines generate heat during operation, which can affect the performance and longevity of the laser source. Cooling systems, such as air cooling or water cooling, are used to dissipate heat and maintain optimal operating temperatures. Efficient cooling systems ensure consistent performance and prevent overheating.

Rotary Attachments

Rotary attachments are optional accessories that enable laser marking and engraving on cylindrical objects, such as pipes, tubes, and rings. These attachments rotate the object during the marking process, ensuring even and precise marks around the circumference. Rotary attachments expand the versatility of laser machines, allowing for the marking of a wider range of products.

Safety Features

Safety is a critical consideration in laser marking and engraving machines. These machines are equipped with safety features, such as protective enclosures, interlock systems, and emergency stop buttons, to ensure operator safety. Protective enclosures shield operators from laser radiation and prevent accidental exposure. Interlock systems disable the laser when the enclosure is open, and emergency stop buttons provide immediate shutdown in case of emergencies.

Software Integration

Laser marking and engraving machines are compatible with various software programs that enable design creation, parameter adjustment, and process control. CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software allow users to create detailed designs and generate tool paths for the laser machine to follow. Advanced software features, such as simulation and optimization, help users visualize and refine their projects before marking.

评论

发表评论