CNC Tomb Stone Engraving Machine

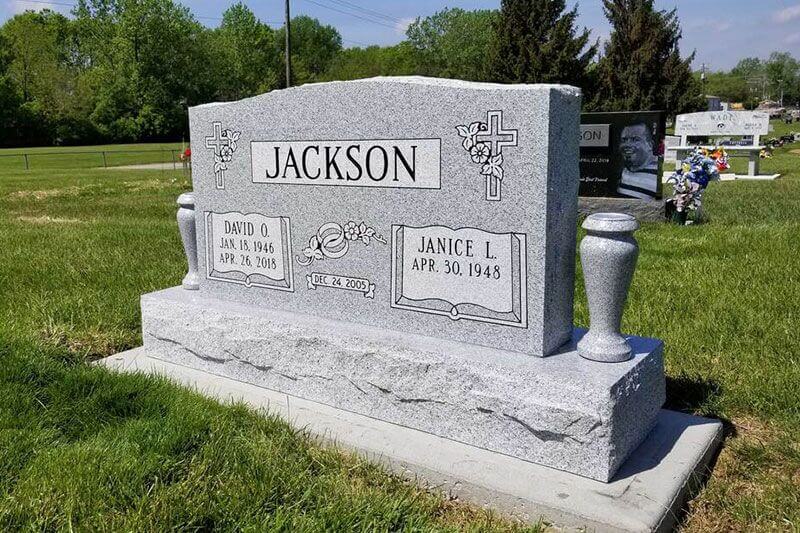

CNC tomb stone engraving machines are specialized CNC routers and engravers designed for stone surfaces used in headstones, memorial plaques, and cemetery monuments. They enable precise inscriptions, portraits, logos, and intricate reliefs on granite, marble, and other stone substrates with repeatable quality. Whether you’re a memorial shop, sculptor, or gravestone fabricator, a dedicated CNC tomb stone engraver can improve edge quality, speed, and customization while reducing manual carving labor and tool wear.

A CNC tomb stone engraving machine is a computer-controlled cutting/engraving system that uses rotary or diamond-tipped tooling to carve, engrave, and texture stone surfaces.

The affordable stone CNC router machine designed by iGOLDENCNC uses a high-strength mechanical structure, which is very suitable for manufacturers in the stone processing industry. It adopts imported linear guide rails to ensure accuracy and provides a set of competitive configurations.

Best Stone Engraving Machine Features

- Stone-focused cutting and engraving: Optimized for granite, marble, limestone, and engineered stone.

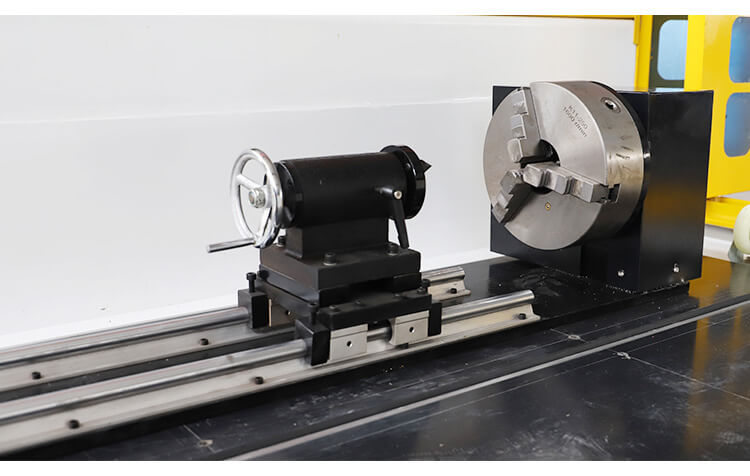

- 3-axis or multi-axis capability: X/Y movement for flat surfaces; Z for depth control; rotary axes for curved profiles on cylindrical memorials.

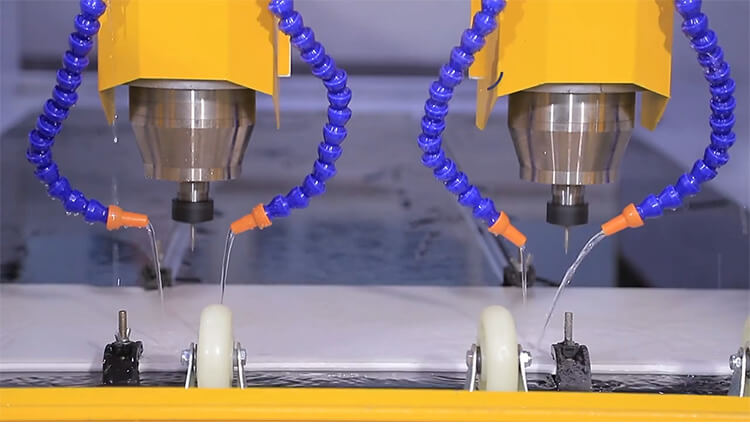

- Diamond tooling or carbide bits: Durable tools designed for hard stone and fine detail.

- Water or air cooling and dust control: To manage heat, dust, and slurry from stone machining.

- CAM/CAD integration: Toolpaths generated from 2D or 3D designs for precise lettering, portraits, and relief work.

- Steel tube lathe bed,low center of gravity,strong bearing capacity,not easy to deformation,stable and reliable operation.

In the memorial industry, the creation of lasting, personalized gravestones and headstones is of utmost importance. Gravestone engraving machines play a crucial role in this process, enabling monument companies and memorial providers to efficiently and accurately engrave text, images, and intricate designs onto a variety of memorial stone materials.

Key Features of Stone Engraving Machines Include

Computer numerical control (CNC) capabilities

Many modern stone engravers are CNC-controlled, allowing for highly precise and repeatable engraving based on digital designs.

Rotary engraving

Rotary engravers use a spinning cutting tool to carve into the stone surface, enabling engraving of curved or irregular shapes.

3D engraving

More advanced machines can create 3D relief carvings by controlling the depth of the engraving.

Varying tool sizes

Machines accommodate different sized cutting tools to allow for engraving of varying levels of detail. Dust collection systems – Integrated dust collection helps keep the work area clean during the engraving process.

Gravestone Engraving Machines

These are specialized CNC (computer numerical control) engraving machines designed specifically for engraving text, images, and designs onto gravestones, headstones, and memorial markers.

Stone Engraving Machine Kits / Parts

The machines use carbide or diamond-tipped cutting tools to precisely carve the stone surface, creating a clean, high-quality engraved finish. Common materials engraved include granite, marble, limestone, and other types of memorial stone.

High configuration CNC stone router: Heavy-duty stone CNC machine has a T-shaped bed for seamless welding of generous square tubes, steel gantry, servo motor, 7.5kw spindle, and more advanced CNC controller. The working speed of the machine can be 10000mm/min.

Gravestone engraving machine often have a rotary engraving capability, allowing for engraving of curved surfaces.

Many models offer 3D engraving capabilities to create raised text and bas-relief carvings. The machines are programmed with specialized CAD/CAM software to translate digital designs into the engraved output.

Stone Engraving Machine Kits / Parts

评论

发表评论