Stone Water Jet Cutting Machine

In the realm of modern manufacturing and construction, the stone water jet cutting machine stands as a beacon of innovation and precision. Ideal for cutting granite or marble countertops to custom shapes and sizes, including sink cutouts and intricate edge profiles.This advanced technology has transformed the way we approach stone cutting, offering unparalleled accuracy and efficiency.

Stone Water Jet Cutting Machine

A stone water jet cutting machine is a sophisticated device that utilizes a high-pressure stream of water, often mixed with abrasive materials, to cut through stone and other hard materials. This method is renowned for its precision and ability to create intricate designs without compromising the integrity of the material.

In the field of architecture, stone water jet cutting machines are invaluable for creating intricate designs and patterns in stone surfaces. From detailed facades to custom flooring, the precision of water jet cutting allows architects to bring their visions to life with unparalleled accuracy.

Stone water jet cutting machines can cut a wide range of materials, including granite, marble, slate, and even metals and glass

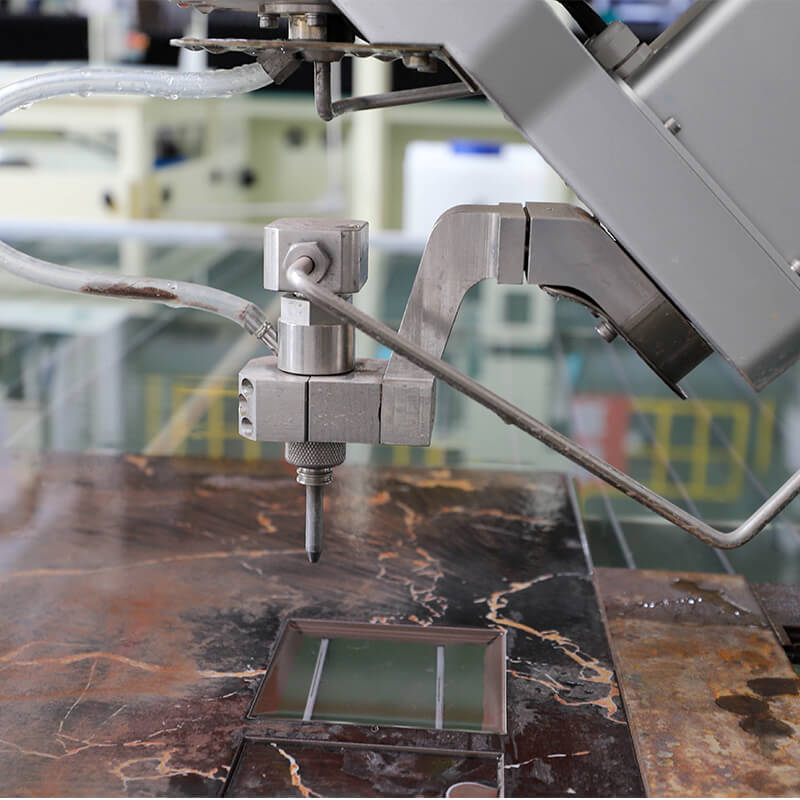

A/C Five-Axis Cutting Head

The 3D water jet cutter machine has five axes, 3 linear spindles and 2 rotating spindles. It has been designed for both pure 3D cut and 2D 1/2 cut (flat cut with bevel), without losing 2D (flat) cut functionality. Its design features offer great work possibilities.

Especially its infinite rotation in the C axis, which avoids the need to rewind with a consequent reduction in working times and a lower risk of reducing the cut quality. On the rotating frame of the C-axis, it is possible to connect the height adjustment and anti-collision control module.

Laser positioning

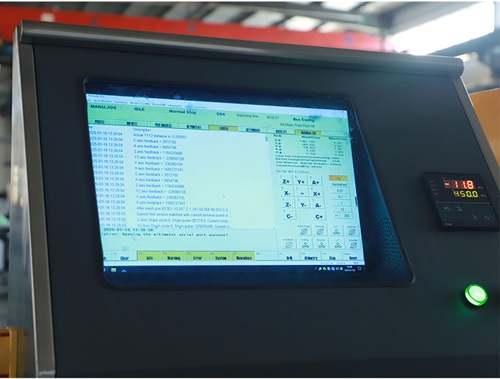

Dedicated water jet cutting software with graphic simulation running function, graphic input automatic programming function.

- Support for DXF files.

- Support forward and reverse processing functions.

- Uniform speed control function.

- Two modes of segmentation and smooth machining.

- Automatic processing with small arc speed.

- Coordinate recovery function after power off.

- Double lift speed parameter function.

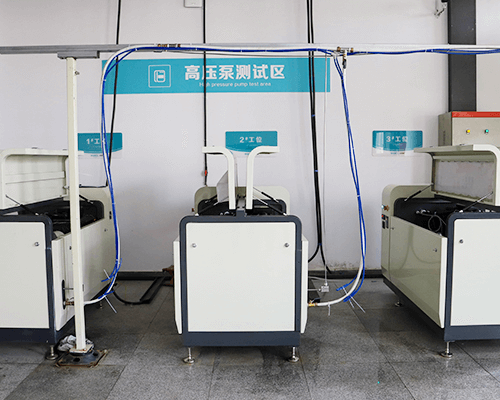

HP servo direct drive pump

Small weight: The total weight of direct drive pump is less than 600kg, and the movement is flexible. • Beautiful appearance: reasonable structure design, beautiful appearance, because the direct drive pump has no hydraulic system, so as to avoid the leakage of hydraulic oil (hydraulic seal will be damaged for a long time, resulting in hydraulic oil leakage), eliminate the pollution of oil stains to equipment.

Abrasive feeder

Provide sand storage function for water knife, and automatically transport sand to the sand bucket. It can improve the automation degree of equipment and reduce the labor intensity of operators. The high precision sensor alerts the operator when sand is needed and can be used for 8-10 hours. No electronic control, simple operation, reliable, maintenance-free.

Stone Water Jet Cutting Machine Industries & Applications

Industrial Manufacturing

In industrial settings, these machines are used to cut and shape components for machinery and equipment. The ability to cut through thick and hard materials with ease makes them a preferred choice in manufacturing processes.

Artistic Creations

Artists and sculptors utilize stone water jet cutting machines to craft intricate sculptures and art pieces. The precision and versatility of the technology allow for the creation of complex designs that would be challenging to achieve with traditional methods.

Custom Signage

For businesses and organizations, custom signage made from stone offers a unique and durable option. Water jet cutting machines enable the creation of detailed logos and text, providing a professional and lasting impression.

评论

发表评论